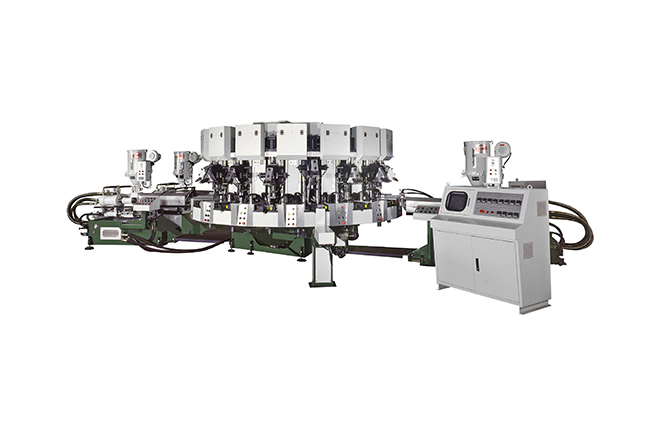

Rotary Type Automatic Single/Two/Three Color Soles Jointing & Ejecting Moulding Machine has a lighting electronic digital control system and a computer that are synchronously connected. There is not only precise control in simple operation, but also accurate machine movement. It is equipped with a spiral specially designed by our factory, which can make high-pressure Injection is completed instantly. Therefore, the fusion between the upper and the sole is excellent, resulting in a more beautiful and durable product.

Common applications of our rotary type automatic single/two /three color sports shoe injection molding machines include:

- Reduce manpower: These machines are widely used in the shoemaking industry to replace traditional complicated processes such as uppers gluing, sole gluing, and sole pressing with one-time shoemaking procedures.

- Multi-color efficient production: The machine allows the creation of sneakers with unique color combinations, patterns and gradients, which enhancing the aesthetic feeling of the final product. One/two/three color sneaker injection molding machines facilitate an efficient production process. It's good to improve the productivity of producing sports shoes in different color combinations.

- Complex designs: Some machines utilize the capabilities of multi-color injection molding technology to produce sneakers with complex designs and color patterns.

- Environmental sustainability: The machine can use recycled secondary materials. Promote environmental sustainability by reducing waste in the production of sports shoes.

- The mold is easy to disassemble and assemble: the mold is easy to install and disassemble. You only need to remove the screws on the mold to replace it.

- Computer control: This machine adopts fully automatic computer control, which is easy to operate and can automatically detect system abnormalities, making maintenance time shorter and easier to maintain.

- Precise control: Optical components combined with computer control make injection volume control more precise and easier to operate. Different injection volumes can be set for different mold stations to ensure stable production.

- Automation: After the mold injectes to a certain amount, the disc can be automatically moved by hydraulic pressure. The opening and closing of the mold and injection are all controlled automatically.